Come along with Marie Blanchet and discover our site!

THEME TO EXPLORE: Marie Blanchet

Marie Blanchet is seventeen. She has been working at the cotton mill in the weaving department since the age of three. Young as she was, she would bring her father’s lunch to him and, during the dinner hour, she learned the basics of the trade. At age eleven, she quit school in order to help her mother with the housework and to take care of her younger brothers and sisters. Including Marie and her father, there were six in the same family who worked at the mill.

The Blanchet’s lived in the Bellerive quarter, to the west of the mill. They owned a small woodframe house with two storeys. There were two rooms on the first floor—a good-sized kitchen and a living room—and four bedrooms on the second floor. Marie shared a bedroom with two younger sisters. There wasn’t a lot of room to move around but she didn’t complain because she had never known a more comfortable place.

ACTIVITY / CLASSROOM DISCUSSION

In the "Urban Development" section, you will discover a completely different quarter. This section was built by Montreal Cotton.

QUESTIONS

Who was this section for?

Who were these people?

What was special about this quarter?

SOURCE: Urban Development

THEME TO EXPLORE: From 6 to 5

“I get up a 5 in the morning to go to work at 6:15. You can’t afford to be late! A single minute past your shift-start time and you’re docked one half hour… At 12:15, the whistle signals my first break, after 6 hours of work. Quickly, I have lunch next to the machines with my friends. I only have half an hour! Then I work all afternoon until 5:30. I spend nearly 11 hours per day at my machine, earning $7 for a 60-hour workweek. My father repairs the looms and earns about $12 per week, and my younger brother has to settle for $4.50. With all that money, our mother can see to our needs. We have everything we need at home… except for time, as we also work Saturdays until noon.”

“At home, we have supper at 6:30. Afterwards, I help my mother with household chores. Then, I don’t have to count sheep to get to sleep, at 9 o’clock – they come and get me straight away and I spend the night spinning their wool in my dreams…”

CLASSROOM ACTIVITY I

The days are long. Industrialisation completely transformed work ethics.

QUESTION

How did this industry expand in Canada?

SOURCES : Industrialisation in Canada | Introduction et The Birth of Industrialisation

CHALLENGE

Place the following in the order that was needed to establish a national policy:

• Financing the railroad

• Immigration policy

• Raising custom duties on imports

• Opening of new lands and industries

• Creation of new export markets

QUESTION

Why did people want to work in a factory?

SOURCE: Hope for a Better Life

QUESTION

What language was spoken at work?

SOURCE: An Anglophone World

CLASSROOM ACTIVITY II

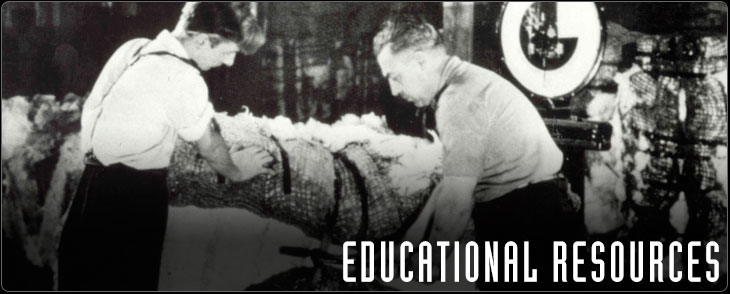

Working conditions in a textile mill are very harsh. Carding cotton creates a lot of dust. Also, to make sure the threads do not break, humidity levels have to be kept high, which leads to respiratory problems. Many workers complain about the noise, which damages hearing, and unbearable heat, especially during summer. The machines vibrate constantly, causing bone and nerve damage. The work itself is not that difficult, but requires constant alertness and causes high stress levels with associated repercussions. To accomplish their tasks, workers have to stay on their feet all day long; they even have to eat lunch next to their machines. All these conditions, in addition to fatigue, can lead to accidents and injuries, but also loss of appetite and anemia.

QUESTION

Were laws passed to reduce the risks?

SOURCE: Working Conditions

QUESTION

Why did the employer seem to care so little for his employees?

THEME TO EXPLORE: Les étapes de traitement du coton

STEP 1: DUSTING OFF THE CLOUDS

“I like the little iron bridge alongside the west side of the plant, the oldest part. I use it to get to work every morning… and when I leave!

The raw cotton is delivered by ship in 500-pound bales. Before it can be spun, it must be cleaned. A machine dries it and removes the dust. Once the raw cotton has been cleaned, it goes through four main processes.”

STEP 2: CARDING COTTON... INTO SMALL STRINGS

“First, the raw cotton is carded. To do so, cylinders equipped with fine needles separate the fibres and align them in parallel, thus forming a round cotton cable about one inch in diameter. The verb “to card” comes from the French “chardon”, or thistle, as the spiny head of this plant was used to manually separate wool and cotton fibres in the past.”

"A good stretch before getting down to brass tacks!"

“The cotton cable is then stretched, twisted, processed into thread, and rolled onto spools. It can be sold as such, or weaved.”

STEP 3: GNIVAEW… WEAVING… GNIVAEW… WEAVING …

“I work in the weaving department, where I make sure the looms are working properly. These machines use mechanized shuttles. They move back and forth, interlacing the threads to make fabric.”

STEP 4: READY FOR SHIPPING

“Once weaved, the cotton is washed and whitened one more time. Our plant does not dye the fabric, but others do, like the Magog facility. When fully processed in the textile mill, the cotton is sold as rolls of white fabric.”

CLASSROOM ACTIVITY

Certain conditions are necessary to set up a factory.

Navigate the site to find:

• The necessary environmental situation,

• The support structures,

• The economic benefits.

SOURCE: All of the From One Continent to Another section.

THEME TO EXPLORE: Knowhow and courage handed down from mother to daughter…

“It’s very hot and humid in the room where I work. Also, hundreds of looms operating at the same time make infernal noise. My job is difficult even though it does not require physical strength. I spend 11 hours per day standing and must stay alert to make sure all the looms are working properly. It’s important that they all work because I’m paid by the length of cotton fabric I can produce.”

In 1911, 39% of the cotton industry labour force was made up of women, and 15% were children (boys and girls) under 16 years of age. Like her colleagues, Marie was a member of the Canadian Federation of Textile Workers, which totalled about 7,000 members, including nearly all the Valleyfield cotton mill employees. According to Marie, the union achieved higher wages and better working conditions for plant employees. Unfortunately, Valleyfield workers almost lost those assets in 1908. Their union had taken a heavy blow from the previous strike and the Montreal Cotton had lowered wages by 10%. To make up for that loss, Marie accepted to increase her workload by supervising two extra looms. Wage cutbacks and unemployment were constant threats.

CLASSROOM ACTIVITY

Why did the workers at Montreal Cotton often go on strike?

SOURCE: Strikes

How many days did the longest strike at Montreal Cotton last?

Who was Madeleine Parent ?

SOURCE: Legacy

THEME TO EXPLORE: Madame Blanchet Song

Despite long hours and difficult conditions at work, Marie was not unhappy. She was soon to marry a textile mill employee and hoped that their children would learn the spinning and weaving trade. Cotton was her livelihood, that’s just how things were.

CLASSROOM ACTIVITY I

QUESTION

And yourself … would you have liked to work at Montreal Cotton?

QUESTION

Do you think that working conditions are still like they were in Marie’s time?

QUESTION

Do you think that textile mills elsewhere in the world have working conditions similar to those in Marie’s time?

CLASSROOM ACTIVITY II

Learn more by watching online:

• "Modern Times" by Charlie Chaplin,

• "Black Cotton" by Julien Després and Jerome Polidor,

• "On the Trail of Fairtrade Cotton" by Max Haverlaad.